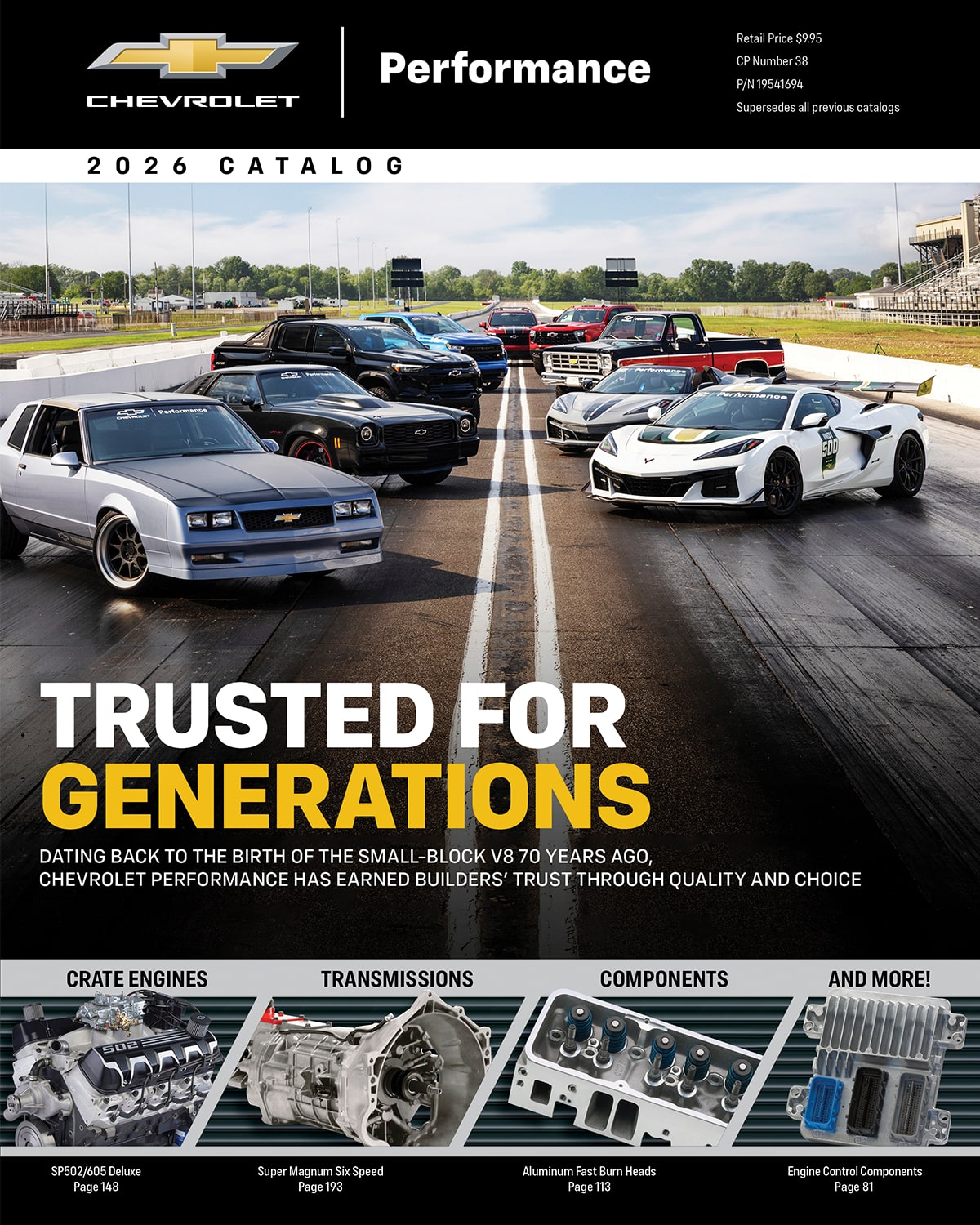

Everything needed to make a project into a performer.

Explore This Page

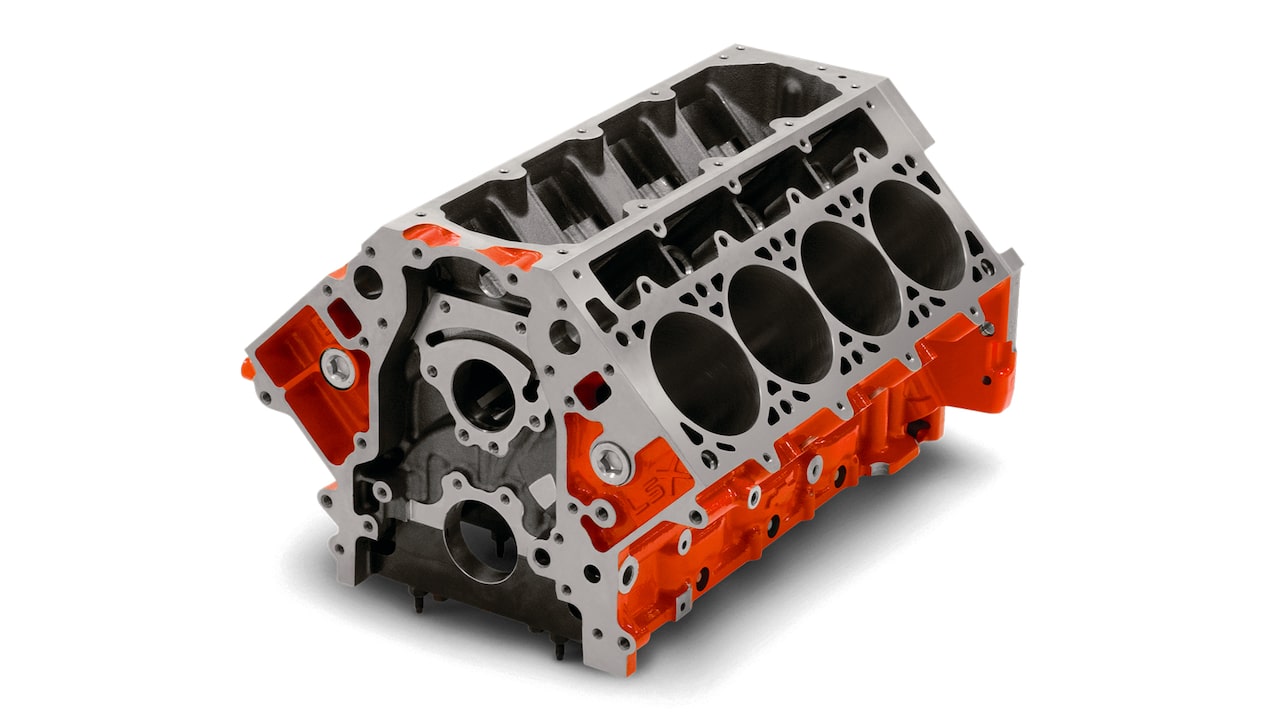

LS/LT/LSX Components

The source for factory-engineered LS, LT and LSX engine parts.

Top Sellers

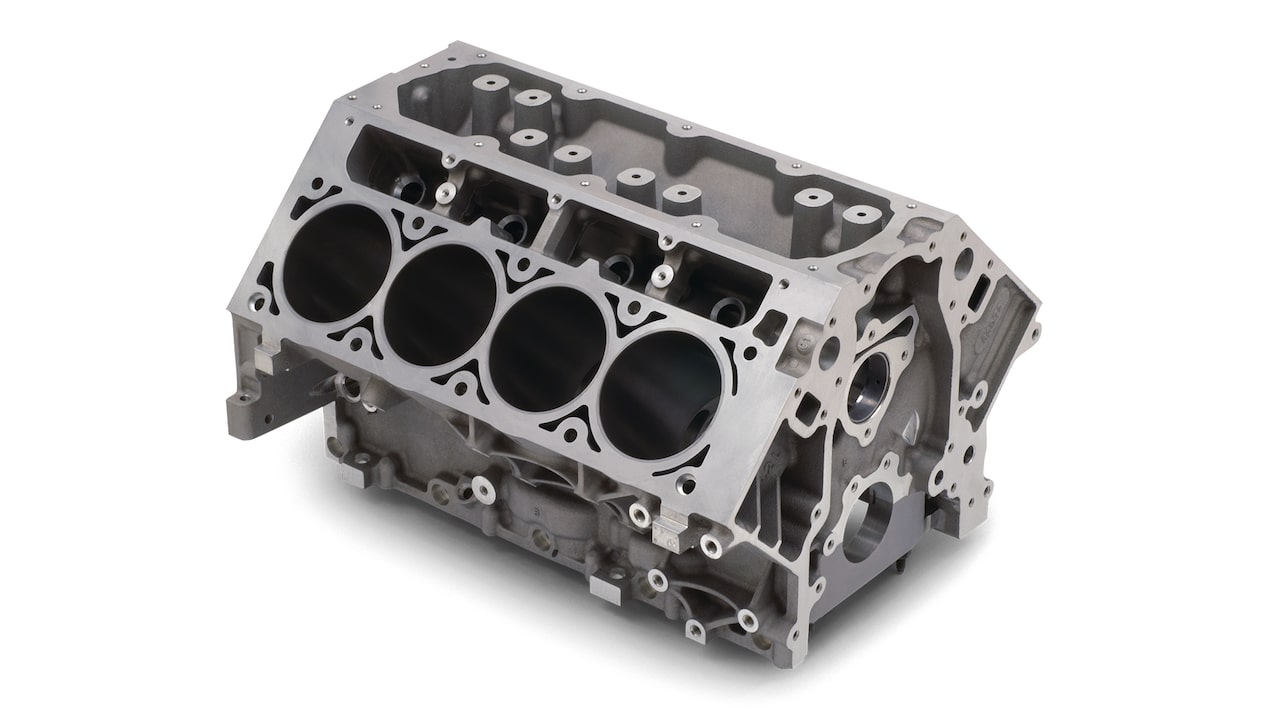

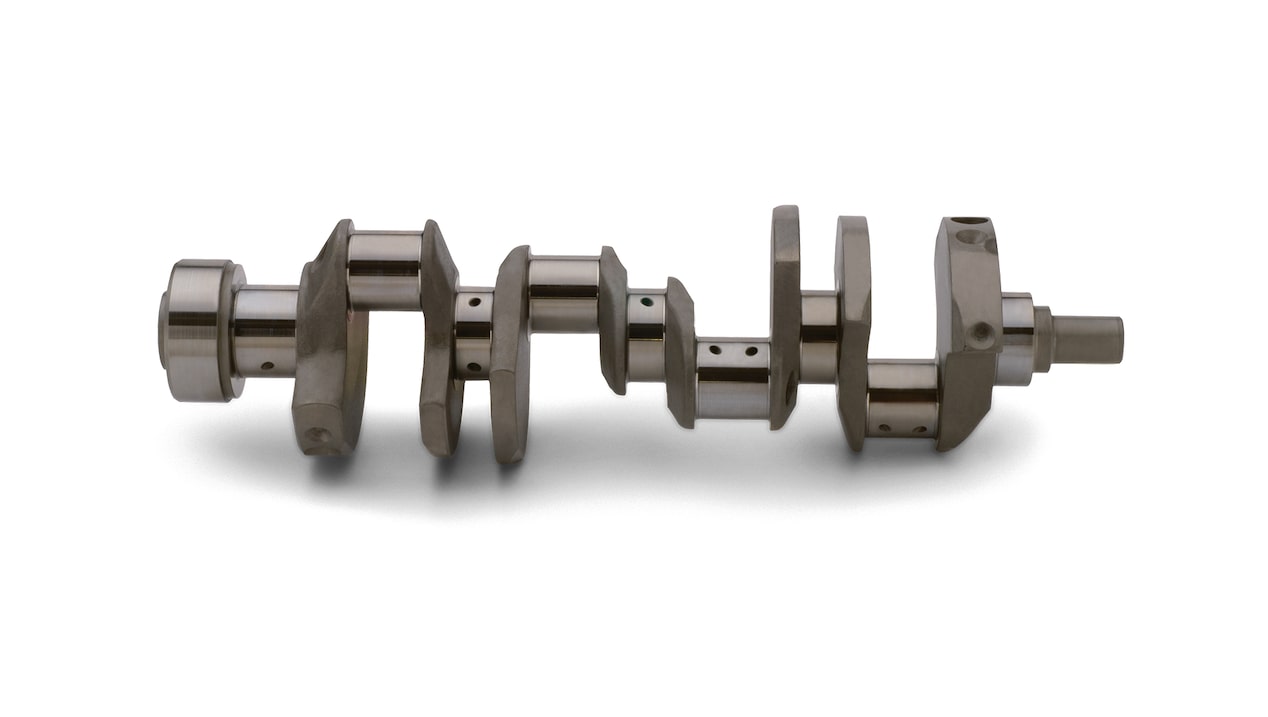

Small-Block Performance Engine Components

Tested to the same rigorous standards as the engines they’re designed for.

Top Sellers

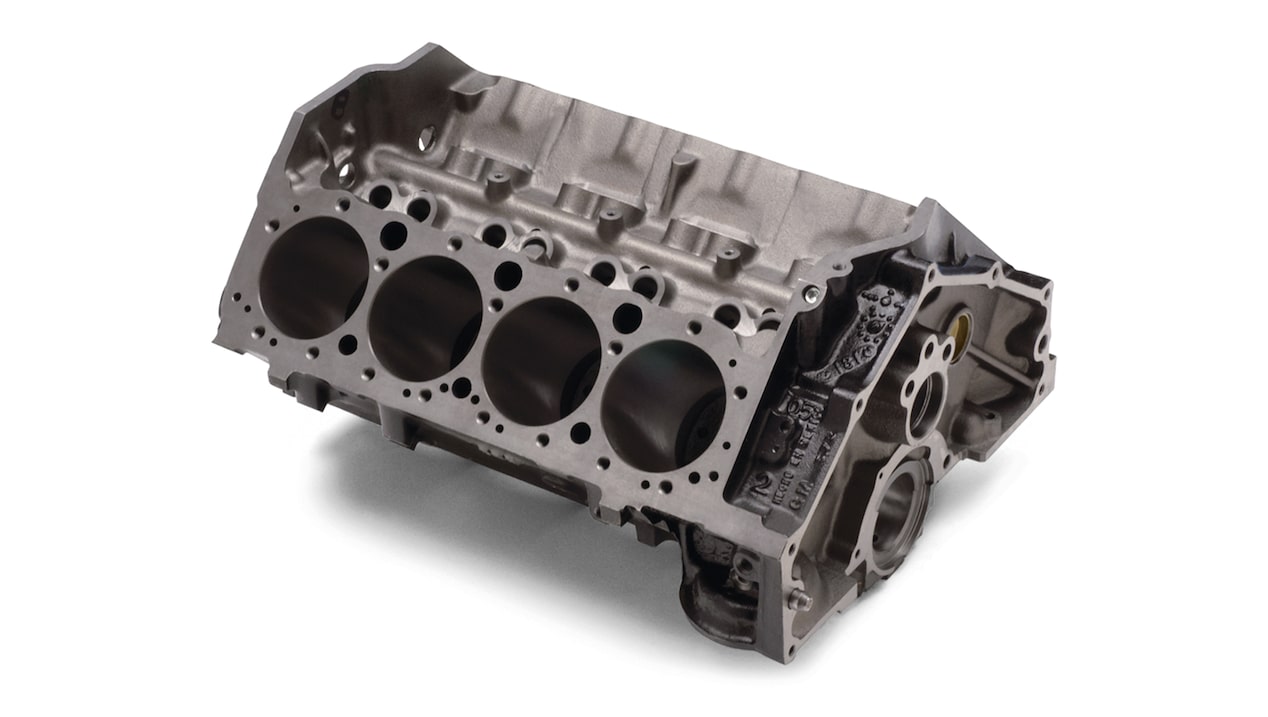

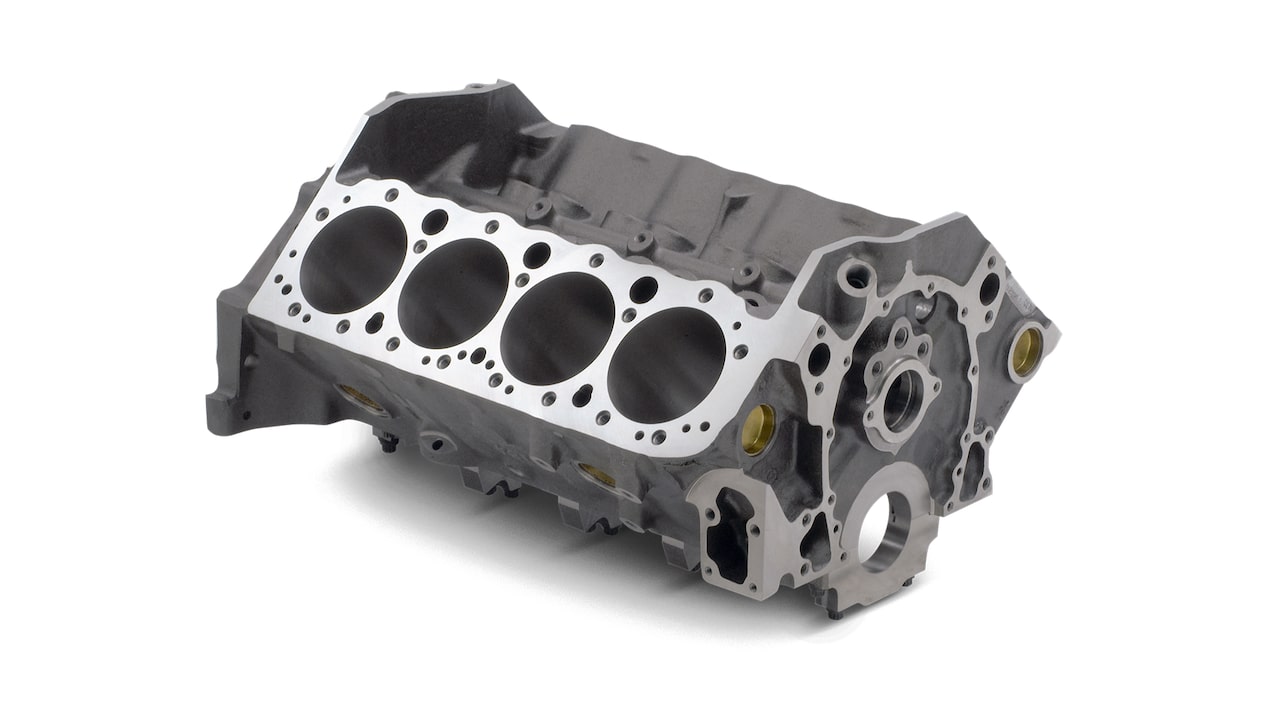

Big-Block Performance Engine Components

Tons of choices and combinations for building the ultimate Big-Block engine.

Top Sellers

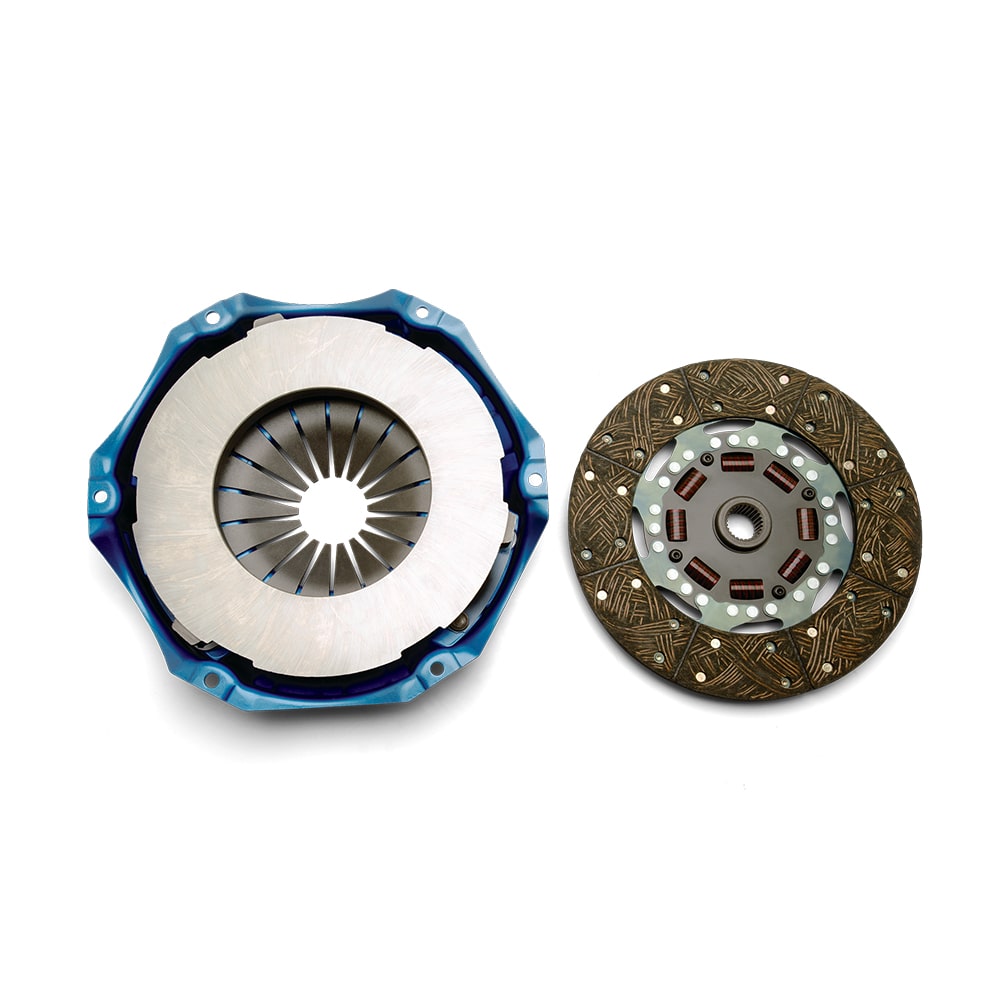

Transmission Components

The clear choice for complementing Chevrolet Performance Crate Engines and Transmissions.

Connect With Us

Offers, news and more all directly from Chevrolet Performance.

Follow our official Chevrolet Performance social media channels. Tag us in your #ChevroletPerformance posts with @ChevroletPerformance

.png?imwidth=1200)